Advanced Cell Chemistry (ACC) refers to new generation advanced storage technologies with much higher energy densities (both volumetric and gravimetric) than conventional ones as well as capabilities for power output/ charge acceptance that are an order of magnitude higher than traditional batteries. As in conventional technologies these too store electric energy as chemical energy and convert it to electric energy as and when required.

Lithium has one the highest specific energies among various elements at 43 MJ/ kg (gasoline at 46.4 MJ/ kg is comparable). Lithium-ion batteries with energy densities of 0.36-0.954 MJ/ kg and 0.90-2.49 MJ/ ltr) offer the possibility of lightweight, compact sources of electrical energy. This has led to Lithium-ion batteries gaining popularity in a variety of weight-sensitive applications or where space is a constraint across consumer electronics devices, spacecraft and aircraft and mobility. Recent advancements have also enhanced the cycle life of Lithium-ion batteries making these a highly viable alternative for powering transportation, general mobility, material handling, and energy storage applications with a very competitive levelized cost of energy (LCoE). As manufacturing capacity for Lithium-ion cells grows, there is increasing adoption of electrification of mobility as well as a shift to renewables, costs of input raw materials and processing costs should drop further. This will lead to much greater expansion of the market for Lithium-ion batteries.

Nsure Energy has adopted the LFP chemistry in preference to NMC and other chemistries. The major advantage of this technology is that it offers greater thermal stability and thus safer batteries that last longer, are more affordable, and more importantly that suit the Indian tropical climate.

As our cells will not contain ternary metals such as nickel nor cobalt, this reduces the risk of fire significantly and it mitigates the environmental impact of used end-of-life cells.

Our approach will be aimed at making the largest possible cells for various applications in order to minimize the overall cost per cycle and increase energy density at a pack level.

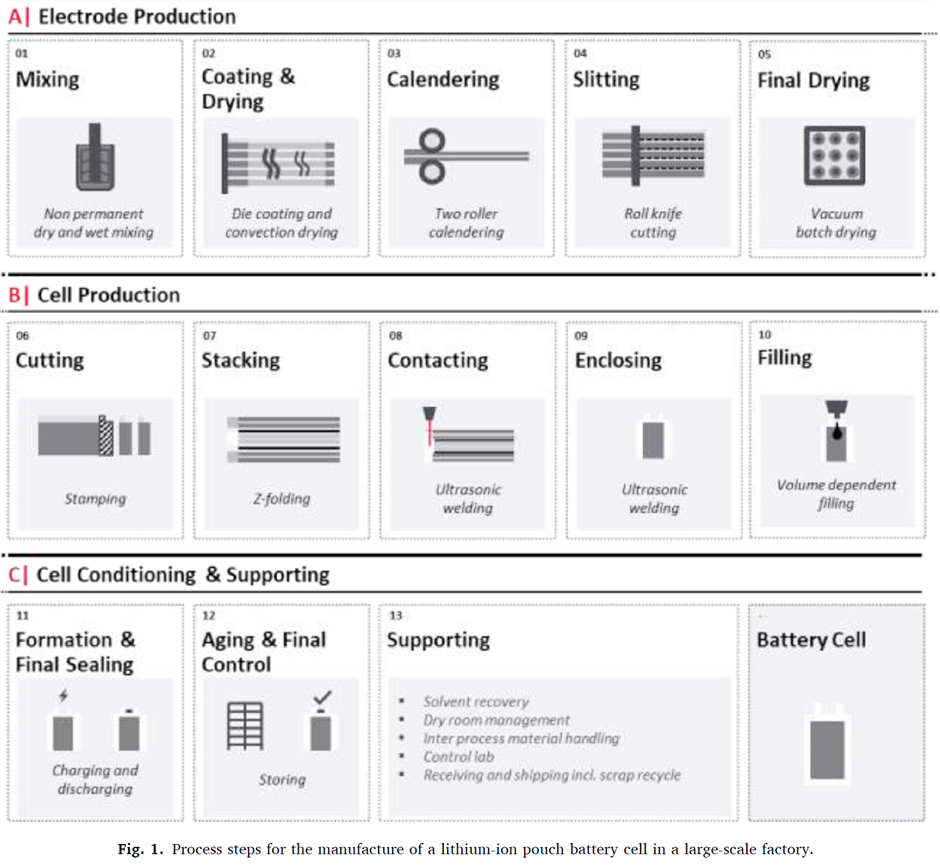

Manufacturing Process

Comparison of Lithium Chemistries predominant in India

| Chemistry | Li Iron Phosphate (LFP) |

Li Nickel Manganese Cobalt Oxide (NMC) | Li Titanate Oxide (LTO) |

|---|---|---|---|

| Short form | Li-phosphate | NMC | Li-titanate |

| Abbreviation | LiFePO4 | LiNiMnCoO2 | Li2 TiO3 |

| Nominal voltage | 3.20V (3.30V) | 3.60V (3.70V) | 2.40V |

| Specific Energy | 120–160Wh/kg | 150–220Wh/kg | 70–80Wh/kg |

| Charge rate | 1C (3h) | 0.7–1C (3h) | 1C (5C max) |

| Discharge rate | 1C–3C | 1–2C | 10C possible |

| Cycle life (ideal) | 2000–3000 | 1000–2000 | 3,000–7,000 |

| Thermal runaway | 270°C (safe at full charge) | 210°C (higher when empty) | One of safest Li-ion batteries |

| Packaging | Cylindrical - Prismatic - Pouch | Cylindrical - Prismatic - Pouch | Prismatic |

| History | 1996 | 2008 | 2008 |

| Applications | Stationary with high currents and endurance | E-bikes, medical devices, EVs, industrial | UPS, EV, solar street lighting |

| Comments | Flat discharge voltage, high power low capacity, very safe, Low cost, elevated self-discharge. Indian market share has increased significantly in the recent months. | High capacity and high power. Market share is shifting towards Cobalt free chemistries. | Long life, fast charge, wide temperature range and safe. Low capacity, expensive. |